Leave the worries of product damage behind as custom gable bag auto bottom with hanger boxes by Packaging Mania are here to serve you. These boxes are a great choice for businesses looking for product distinction, with a sturdy auto-lock bottom, a gable-like shape, and a hanger at the top for easy hanging. Order our eco-friendly hanger boxes today and get them delivered fast to your doorsteps within 5-7 business days.

Custom gable bag auto bottom are a sure way to grab attention and skyrocket your brand’s sales. This type of packaging is mostly preferred in food industry, and by kids for carrying toys or small items. People use them for gifting purposes as well. With our premium packaging, get ready to provide the most secure storage space to your products, with a stunning closure and simple flat structure that is quite easy to open. We create these boxes with the best prints and designs to grab attention, and place inserts, partitions and pads for extra protection and to serve multiple purposes.

These are specific boxes by style famous for their unique shape, allowing the products to be hung wherever one wants. Basically, it is a hybrid mode of packaging that fuses the aesthetics of both a bag and a box. The bottom of the box automatically locks once these boxes are put into place. The hanger allows for easy carrying without the need for any extra bag. In addition, these boxes can be tailored as per your brand’s theme and offerings with die-cut shapes, finishes, materials, prints, add-ons, and other custom features. Get your custom boxes from Packaging Mania that offers a low MOQ of 100 boxes on bulk orders. in addition, we also share 2D and 3D mock-ups to ensure you are always satisfied with the design we offer. To maximize the product visibility, we can use several add-ons like windows and specific custom features.

The gable-like triangular top of the box is its major draw point that makes these boxes quite easy to carry and lends them functionality like a shopping bag handle. To term “auto bottom” indicates the easy and automatic closure of the box that allows for maximum time-saving. The box features a built-in hanger that lets you hang the box or display racks or in any retail settings in the most hassle-free way.

The sturdy panels at each side of the box are the main reason behind the ultimate strength they lend, and the gable top can be further secured with interlocking flaps. This specific design makes these boxes a top choice for brands across multiple industries. If you take a look around in the market, you are going to find items like clothing, gifts, and accessories placed inside them.

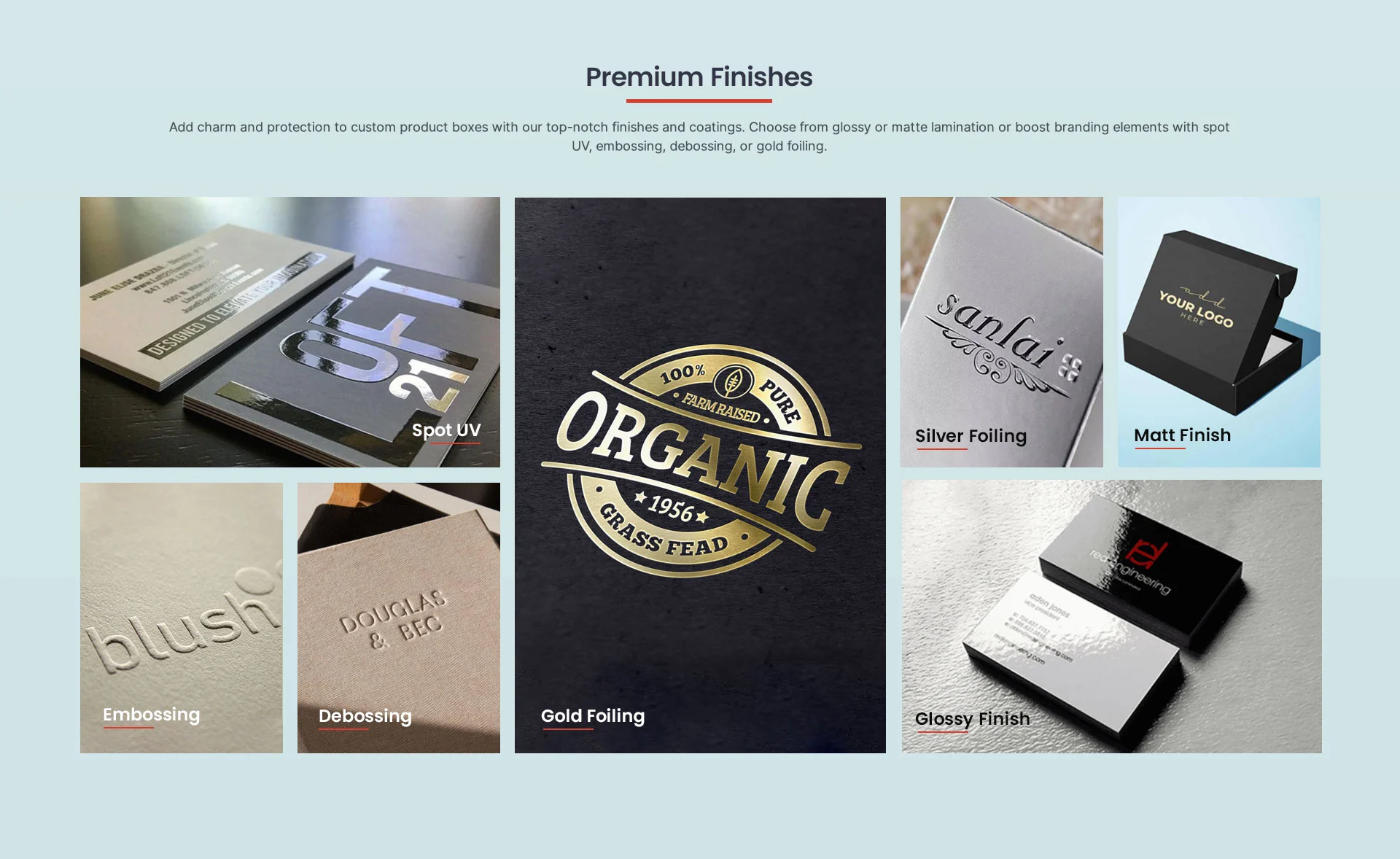

At Packaging Mania, get your dream boxes delivered within the promised time of 5-7 days, with 10-28pt (60lb to 400lb), and material choices including Kraft and E-flute Corrugated. We utilize full-color CMYK and PMS color schemes to bring consistent and crisp colors and prints to your custom gable bag auto bottom with hanger boxes. Choose your preferred material thickness for Kraft or paper stock. Need some glossy or extra tactile touch to these boxes? Opt for our gloss, matte, or aqueous lamination, or choose spot UV/embossing/debossing to bring in more depth to your box design. We use high-end finishes include gold or silver foiling to makes your boxes look stylish and professional. Whether you want a digital sample or a physical one, we can provide you with any as per your preferences.

Customization allows brands to tailor these boxes as per your brand’s needs. The use of high-quality inks helps brands to portray their essential details in the most notable way. Using certain finishes, brands can enhance their existing design or highlight specific areas to boost their market value. Moreover, placing these details strategically on the gable top allows for maximum visibility of these insights when displayed on retail shelves.

The adjustable hanger allows brands to store products of different sizes and display needs. To allow for maximum product visibility, window cutouts can be added to build up more trustworthiness of the brand with its target consumers. Further, die-cut handles and closures can also be added as per your request, to facilitate user convenience even more and add more stylish looks to these boxes. Whatever custom feature you choose for your brand, we assure you of outcomes totally in favor of your brand. Discuss your packaging dreams with us and our experts will work closely with you to discuss further options that can enhance your custom gable bag auto bottom boxes even more.

With Packaging Mania, get attention of all eco-conscious buyers with the planet-supportive nature of our custom gable bag auto bottom boxes. We make each of these boxes with eco-friendly and recyclable materials, sustainable inks, and printing practices that don’t cast any burden on the environment. Our packaging is not only pleasing to the eyes, but also waterproof and resilient at the same time to prevent any accidental harms.

Placing your products in any of our custom gable bag auto bottom with hanger boxes can surely increase their worth. Order custom printed gable bag auto bottom with hanger boxes with us today and get ready to enjoy amazing perks like free shipping and design help, quick turnaround time, discounts up to 30%, and free digital sampling. Send us your needs straightaway at info@packagingmania.com to get a quick quote and one of our representatives will get in touch with you shortly.

All Custom Sizes & Shapes

CMYK, PMS, No Printing

10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated,Bux Board, Cardstock

100 - 500,000

Gloss, Matte, Spot UV

Die Cutting, Gluing, Scoring, Perforation

Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet.

Flat View, 3D Mock-up, Physical Sampling (On request)

5-7 Business Days , Rush

Yes, we offer both inside and outside printing as per your request.

To ensure the end result comes up to your expectations, we provide you with a free digital sample so that you can view it and confirm its status before we pass it for printing.

We use top-quality and eco-friendly Kraft and E-flute Corrugated material to ensure the best protection of your products and a sturdy box structure.

You can choose from any of these finishes we offer:

We've worked with lots of successful industries around the world and have won their confidence & loyalty.