By Blake Harper 15 October 2024

Custom boxes have become the new standard in the packaging industry, and for good reason. They offer perks and benefits that traditional boxes can’t. When brands choose bespoke packaging for their goods, they do it for several reasons, which include design flexibility, better item safety, and low-cost marketing.

Cost is one of the factors that firms choose these boxes over the standard ones, as they are way cheaper. Material efficiency, bulk order discounts, and low shipping charges allow suppliers to ask for a reasonable price for their bespoke packaging. However, when it comes to custom rigid boxes, these cost benefits go out the window. But there are reasons for them to be costly, and this article will detail why rigid box packaging is expensive.

Before we answer the question, let us take a brief look at what is rigid packaging. The reason we have to do that is simple; it will help you better understand why they are expensive when we get to it. These boxes are sturdy and non-collapsible Rigid packaging made of a strong material, such as a thick paperboard or chipboard. The material itself is wrapped in specialty paper, which keeps it contained and makes the box look premier. Unlike regular custom boxes, they maintain their shape and structure and can't be supplied in a flat form. Typically, rigid boxes come with a base and lid. It is a premium packaging solution often used for luxury goods. With the introduction of rigid packaging out of the way, the following is why rigid boxes are expensive:

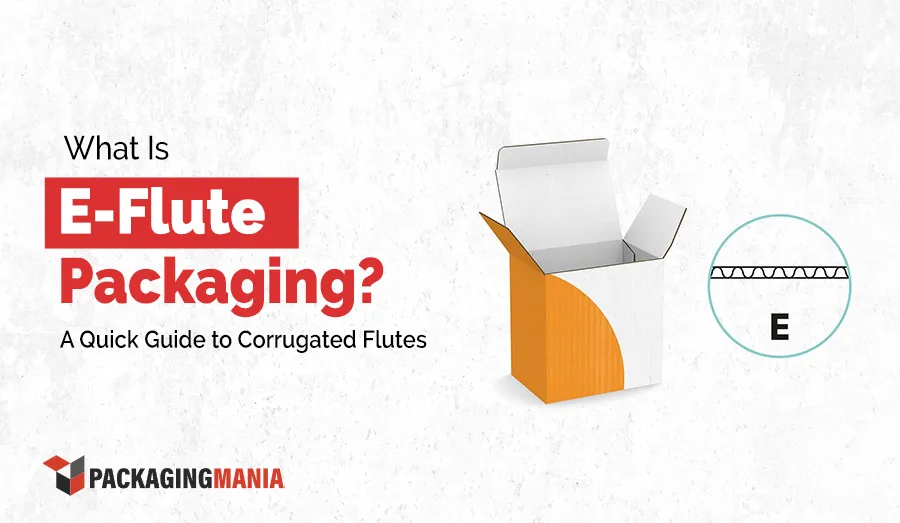

Custom boxes can be changed in any way a brand wants. Not just in terms of looks and utility, but what materials are used to make them. Brands can choose from a variety of materials to make bespoke boxes like Kraft paper, cardboard, or corrugated stock. The choice of material also impacts the cost of packaging, and one reason rigid boxes are costly is the materials used to make them.

As stated, the packaging is made with sturdy materials like chipboard, which is wrapped in specialty paper. These materials not only make the boxes strong and durable but also expensive. However, there is an upside to them, which is they provide even better product safety. Rigid packaging can withstand significant impact and pressure, which keeps the items packed inside safe during shipping. On top of that, they also keep the goods safe from external factors like heat or water. In short, the quality of these materials leads to higher costs.

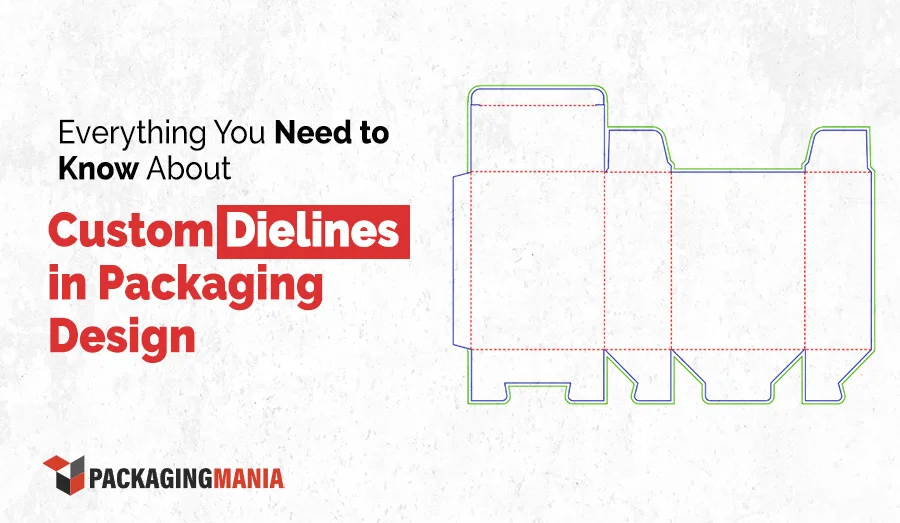

The complexity of the design of these custom boxes is another factor that makes them expensive. We are not just talking about the visual appeal but also the practical side of rigid packaging. These boxes require careful craftsmanship and methods to make. Since these are custom boxes, the shape can vary widely, depending on the brand that is ordering. Unlike standard boxes that come in straightforward shapes, rigid boxes are custom-made as per the size and shape of specific goods. For example, a rigid box for a luxury wristwatch will be very distinct in shape and utility than packaging for jewelry. Such elements increase the design complexity that requires special tools or die cutting, which are costly to use and make rigid boxes expensive.

On top of that, adding features like custom inserts or magnetic closures can further add to the design complexity. While they are worth it as they enhance the visual appeal and use experience, they come with increased labor and material costs. Bespoke outer print is another feature of custom boxes that standard ones can’t provide. Rigid boxes rely on cutting-edge printing methods such as digital printing. These techniques allow for stunning graphics and vivid colors, but this elegance has a price tag as they cost more than the usual methods. The design of these boxes can be further complex if brands choose to use finishes, like spot UV or foil stamping. Sure, they add that extra flair, texture, and visual intrigue, but they also introduce more steps in production. Suddenly, costs can escalate.

Usually, custom boxes are supplied to brands in flat form. Since they are made with materials like Kraft or cardboard, it is easy to collapse and then ship them, which results in them taking less space during transit, and suppliers charge a small fee for it. However, custom rigid boxes are made with sturdy and thick materials like chipboard and can’t be collapsed in a flat form. This means that they have to be shipped in their original form, and they take up more space, and the thick material increases their weight. This results in higher shipping costs compared to custom boxes made with light materials, which is another reason why rigid packaging is costly.

The increased demand for these boxes in various market sectors is another reason why they are expensive. The packaging is often used for high-end luxury goods like jewelry or cosmetics. Given its tailored nature, it acts as an extensive of the product itself, which impacts buyer perception of goods and their behavior. Businesses understand this, and that is why they are willing to invest more in custom rigid boxes. This has led to an increased demand for them, which in turn has skyrocketed the price.

On top of that, online purchasing has also increased the demand for these boxes. The more people buy things online, the need for durable packaging increases. We know that rigid boxes are made with sturdy materials, like chipboard, which makes the rigid boxes durable. This allows them to keep the items safe from damage during transit and has resulted in more businesses using them as the packaging of their choice. This is another market sector with increased demand, which results in inflated prices.

The economy also plays a role in the increased demand and price for rigid packaging. In a booming economy, people tend to spend more on premium goods, and that drives up the demand for quality packaging. But when times get tough, brands often scramble to save a buck, which can put pressure on the rigid box market. Still, some companies stick to their guns, as they understand that even when the chips are down, good packaging matters. It’s not just about looks, it’s about keeping that brand image intact and holding on to loyal customers.

As climate change rages on, the debate about global warming has intensified. This has led to a shift in what buyers want, as they now prefer goods made with sustainable materials or brands that have made green initiatives part of their values. This has resulted in an increased price for custom rigid packaging, and here is how. To attract eco-conscious folks to their goods, businesses are using rigid boxes made with eco-friendly materials. Sourcing such materials as cardboard derived from recycled paper comes at a premium price, which leads to increased production costs.

Now you have the answer to your question: why are custom rigid boxes expensive? The quality of the materials, complexity of the design, increased demand for rigid packaging, higher shipping costs, and more are the reasons why these boxes are so expensive compared to custom boxes made from Kraft or cardboard. However, the premium price of the packaging comes with features that justify it, like enhanced brand perception and better item safety. There is no better bespoke container for luxury or premier products than a rigid box, and that’s a fact.

16 July 2025

28 June 2025